We’re excited to announce that MongoDB and MaintainX are joining forces to help manufacturers achieve excellence in maintenance operations. This joint solution enables a digital thread from raw production data to maintenance execution.

The downtime dilemma: Why manufacturers need change

Unplanned downtime costs manufacturers millions of dollars per hour, disrupting production schedules, straining maintenance operations teams, and erasing profitability. According to Siemens’s "The True Cost of Downtime 2024," each unproductive hour in the automotive sector now costs $2.3 million. Despite more operational data being available from modern, connected machines, most organizations still struggle to connect the dots between real-time operational data and the actions required to prevent equipment failure. This increases MTTA (Mean Time To Acknowledge) and MTTR (Mean Time to Repair), directly impacting revenue and profitability.

For manufacturers across all sectors, achieving maintenance excellence is no longer optional. It’s a foundational pillar of operational excellence. Achieving maintenance excellence requires not only downtime prediction, but also the ability to act instantly and collaboratively across systems and teams.

How the MongoDB-MaintainX solution works

MongoDB and MaintainX are working together to address the gap between operational insight and maintenance execution. We are creating a unified digital thread that connects data from the production floor to the maintenance execution applications.

In the MongoDB-MaintainX solution, MongoDB Atlas serves as the central, unified namespace persistence layer and stores telemetry, maintenance logs, inventory, and resource availability in a flexible document model database. MaintainX, meanwhile, transforms that data into action through digital maintenance work orders, AI-powered technician guidance, and intelligent resource planning, keeping teams coordinated and responsive. Together, we are enabling manufacturers to move from reactive to predictive maintenance, reducing operating costs, increasing equipment uptime and lifespan, and directly impacting our clients' profitability.

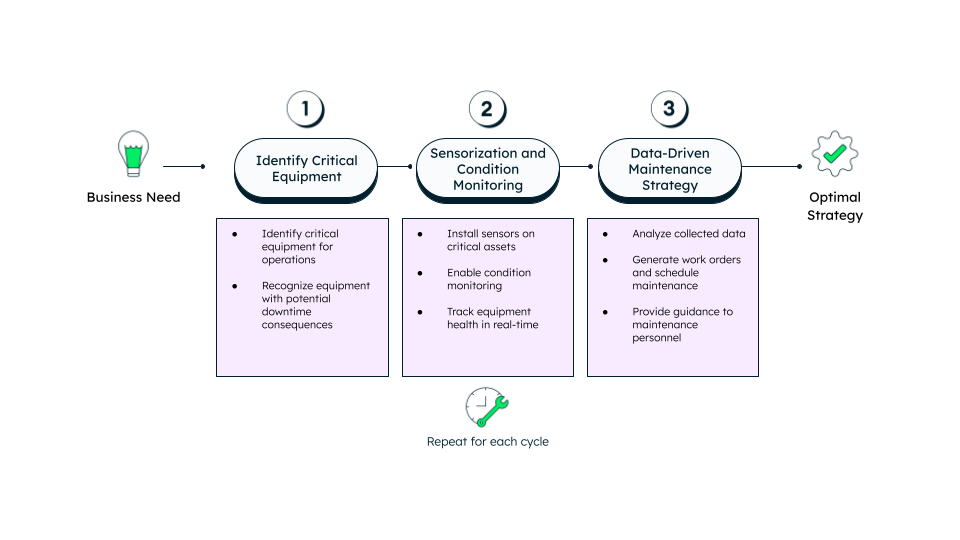

A well-defined maintenance strategy can be a game-changer, driving significant revenue and cost savings. Here's broadly how it works:

First, identify the equipment most crucial to your operations. Downtime for this equipment can lead to bottlenecks and halt production.

Second, equip these critical assets with sensors to enable condition monitoring. This allows you to monitor equipment health in real time, identifying potential issues before they escalate into catastrophic failures.

Third, based on the prediction, the system can generate work orders, schedule maintenance activities, and even guide maintenance personnel. This ensures that maintenance is performed only when necessary, optimizing resource allocation.

This series of activities can deliver tangible benefits, such as higher throughput, lower total maintenance cost, and increased revenue. Indeed, MaintainX customers report:

33% reduction in unplanned downtime (on average)

34% lower parts-inventory costs

39% improvement in overall equipment effectiveness (OEE).

MongoDB Atlas as the persistence layer for Unified Namespace (UNS)

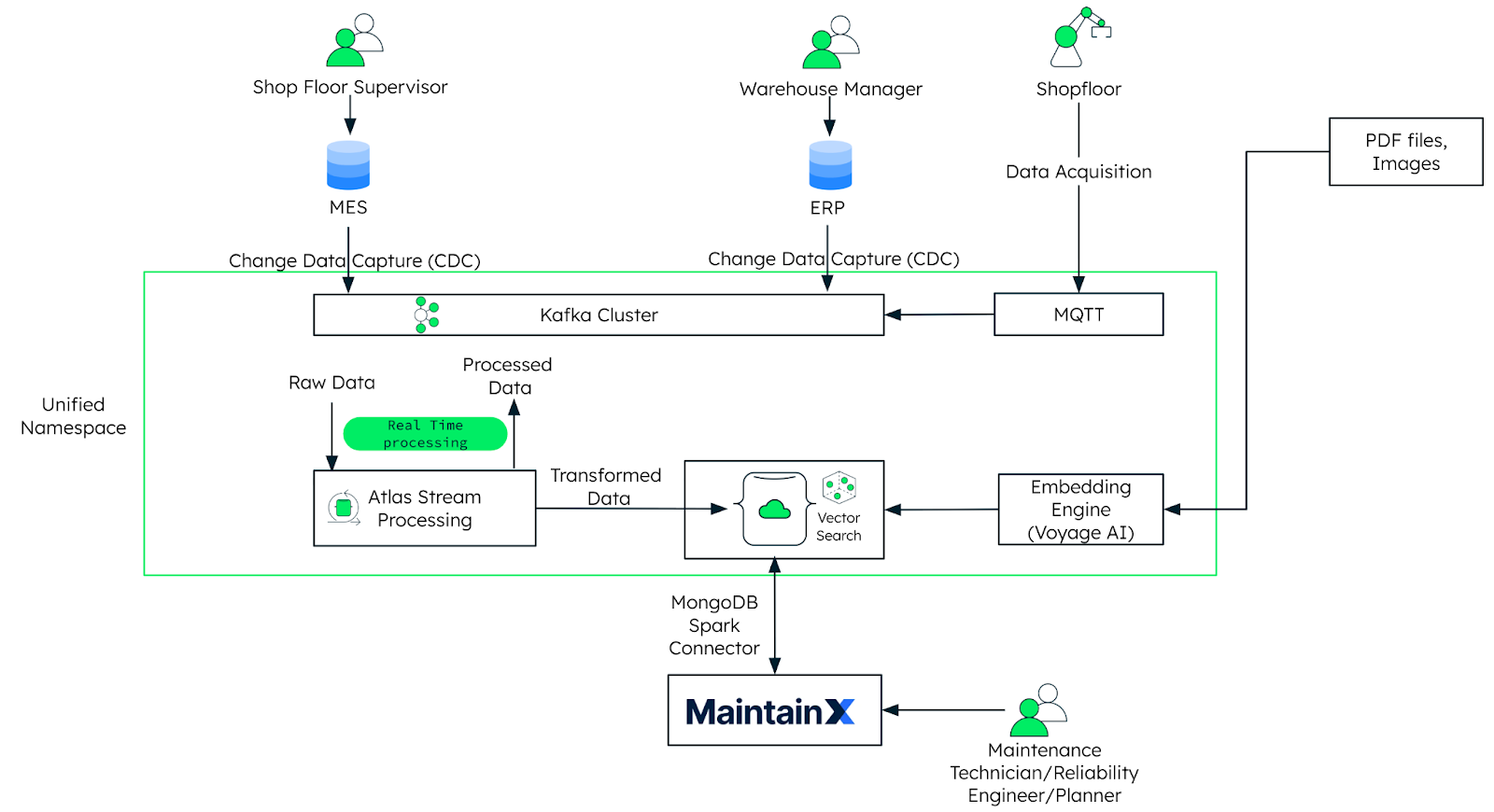

MongoDB Atlas serves as the flexible operational data layer that persists the data of the unified namespace and brings together every piece of operational and maintenance data into a single, intelligent system of action. It ingests telemetry from machine controllers and sensors, collects historical maintenance logs, and aggregates inventory, resource, and schedule data, all in a single flexible document data model. This eliminates the need for MaintainX to wrestle with fragmentation across systems, giving it a single source of truth to act on.

What’s more, MongoDB Atlas Stream Processing can be used to transform raw machine data into relevant information for downstream applications to consume. MongoDB Time Series collections provide scalable storage for machine telemetry, whereas MongoDB Atlas Vector Search enables semantic search across unstructured data such as PDFs and images. Unstructured data is converted into vectors using Voyage AI embedding models. MongoDB Atlas ensures that every signal, alert and record is unified and contextualized before reaching the execution layer.

Once data is captured and organized in MongoDB, MaintainX leverages it to drive real-time operational decisions. Using the MongoDB Spark Connector, MaintainX workflows can be triggered the moment specific thresholds or fault conditions are detected, automatically generating digital work orders, scheduling inspections and surfacing the correct procedures. Maintenance technicians, reliability engineers, and planners gain instant visibility into asset conditions, pending tasks, and resource availability, all powered by the unified namespace data layer living in MongoDB.

This seamless flow of data between MongoDB and MaintainX transforms maintenance management from a reactive process into a continuous, data-driven loop, where insights drive coordinated actions on the shop floor and across sites.

Unlock the future of AI in industrial maintenance and asset management

MongoDB and MaintainX form a robust foundation for the next generation of intelligent maintenance operations. By unifying operations, data management, and maintenance execution, we are enabling manufacturers to build reliable AI-driven workflows that act on real-time insights with precision and speed, driving higher uptime and lower operational and maintenance costs.

Next Steps

To learn more about MongoDB’s role in the manufacturing industry, visit the Manufacturing and Automotive webpage.

Ready to boost your MongoDB skills? Head over to MongoDB Atlas Learning Hub to start learning today.

Explore the MongoDB Solutions Library to discover best practices, ready-to-use templates, and expert guidance for building powerful applications.