It would be easy to conceptualize mobile edge computing (MEC) as a telecommunications-specific technology; but, in fact, edge computing has far-reaching implications for real-world use cases across many different industries. Any organization that requires a solution to common data usage challenges, such as low-latency data processing, cloud-to-network traffic management, Internet of Things (IoT) application development, data sovereignty, and more, can benefit from edge-based architectures.

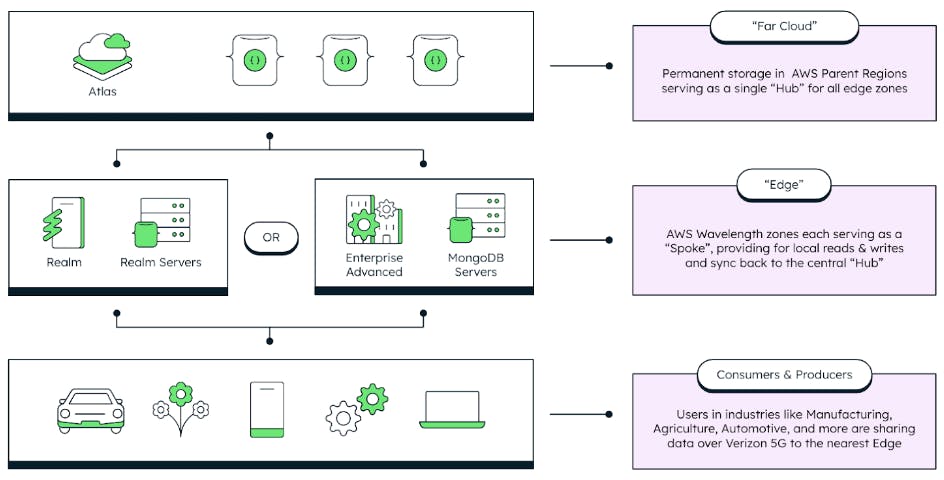

In our previous article, we discussed what mobile edge computing is, how it helps developers increase data usage flexibility, and how Verizon 5G Edge and MongoDB work in conjunction to enable data computing at the edge, as shown in Figure 1.

In this article, we’ll look at real-world examples of how mobile edge computing is transforming the manufacturing, agriculture, and automotive industries.

Smart manufacturing

Modern industrial manufacturing processes are making greater use of connected devices to optimize production while controlling costs. Connected IoT devices exist throughout the process, from sensors on manufacturing equipment to mobile devices used by employees on the factory floor to connected vehicles transporting goods — all generating large amounts of data.

For companies to realize the benefits of all this data, it is critical that the data be processed and analyzed in real time to enable rapid action. Moving this data from the devices to the cloud for processing introduces unnecessary latency and data transmission that can be avoided by processing at the edge.

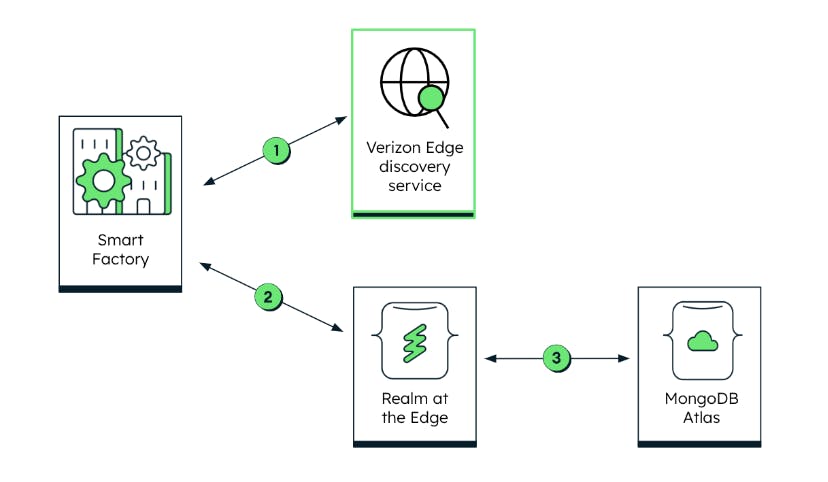

As seen in Figure 2, for example, sensors, devices, and other data sources in the smart factory use the Verizon 5G Edge Discovery Service to determine the optimal edge location. After that, data is sent to the edge where it is processed before being persisted and synchronized with MongoDB Atlas — all in an instant.

Process optimization

Through real-time processing of telemetry data, it’s possible to make automated, near-instantaneous changes to the configuration of industrial machinery in response to data relayed from a production line. Potential benefits of such a process include improved product quality, increased yield, optimization of raw material use, and ability to track standard key performance indicators (KPIs), such as overall equipment efficiency (OEE).

Preventative maintenance

Similar to process optimization, real-time processing of telemetry data can enable the identification of potential impending machinery malfunctions before they occur and result in production downtime. More critically, however, if a situation has the potential either to damage equipment or pose a danger to those working in the vicinity, the ability to automatically perform shut downs as soon as the condition is detected is vital.

Agriculture

One of the most powerful uses of data analytics at scale can be seen in the agriculture sector. For decades, researchers have grappled with challenges such as optimal plant breeding and seed design, which to date have been largely manual processes.

Through purpose-built drones and ground robotics, new ways to conduct in-field inspection using computer vision have been used to collect information on height, biomass, and early vigor, and to detect anomalies. However, these robots are often purpose-built with large data systems on-device, requiring manual labor to upload the data to the cloud for post-processing.

Using the edge, this entire workflow can be optimized. Starting with the ground robotics fleet, the device can be retrofitted with a 5G modem to disintermediate much of the persistent data collection. Instead, the device can collect data locally, extract relevant metadata, and immediately push data to the edge for real-time analytics and anomaly detection.

In this way, field operators can collect insights about the entirety of their operations — across a given crop field or nationwide — without waiting for the completion of a given task.

Automotive

Modern vehicles are more connected than ever before, with almost all models produced today containing embedded SIM cards that enable even more connected experiences. Additionally, parallel advances are being made to enable roadside infrastructure connectivity. Together, these advances will power not just increased data sharing between vehicles but also between vehicles and the surrounding environment (V2V2X).

In the shorter term, edge-based data processing has the potential to yield many benefits both to road users and to vehicle manufacturers.

Data quality and bandwidth optimization

Modern vehicles have the ability to transmit large amounts of data not only in terms of telemetry relating to the status of the vehicle but also in regard to the observed status of the roads.

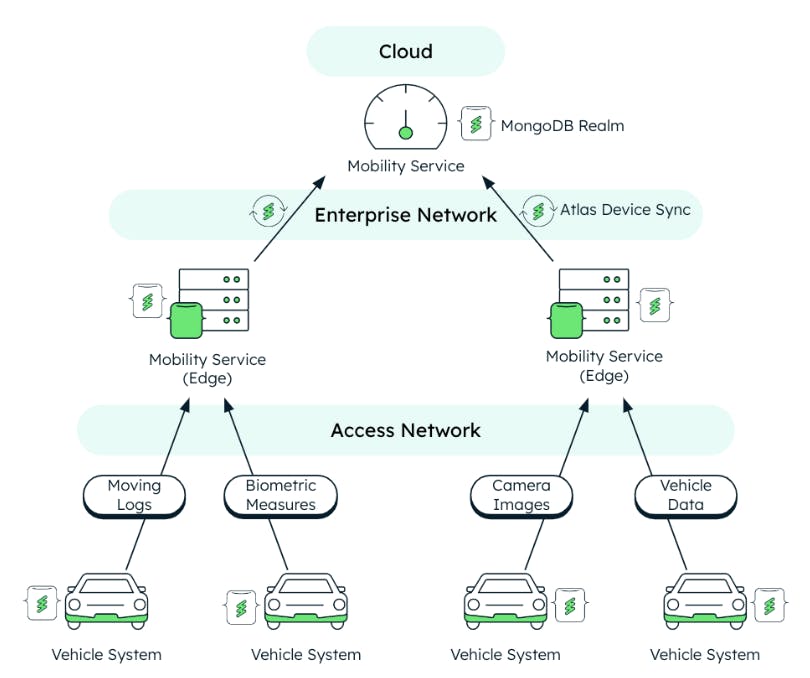

If a vehicle detects that it is in a traffic jam, for example, then it might relay this information so that updates can be made available to other vehicles in the area to alert drivers or replan programmed routes, as shown in Figure 3.

Although this is a useful feature, many vehicles may be reporting the same information. By default, all of this information will be relayed to the cloud for processing, which can result in large amounts of redundant data.

Instead, through edge-based processing:

Data is shared more quickly between vehicles in a given area using only local resources.

Costs relating to cloud-based data transfer are better controlled.

Network bandwidth usage is optimized.

While improving control of network usage is clearly beneficial, arguably a more compelling use of edge-based processing in the automotive industry relates to aggregating data received from many vehicles to improve the quality of data sent to the cloud-based data store.

In the example of a traffic jam, all of the vehicles transmitting information about the road conditions will do so based on their understanding gained through GPS as well as internal sensors. Some vehicles will send more complete or accurate data than others, but, by aggregating the many different data feeds at the edge, this process results in a more accurate, complete representation of the situation.